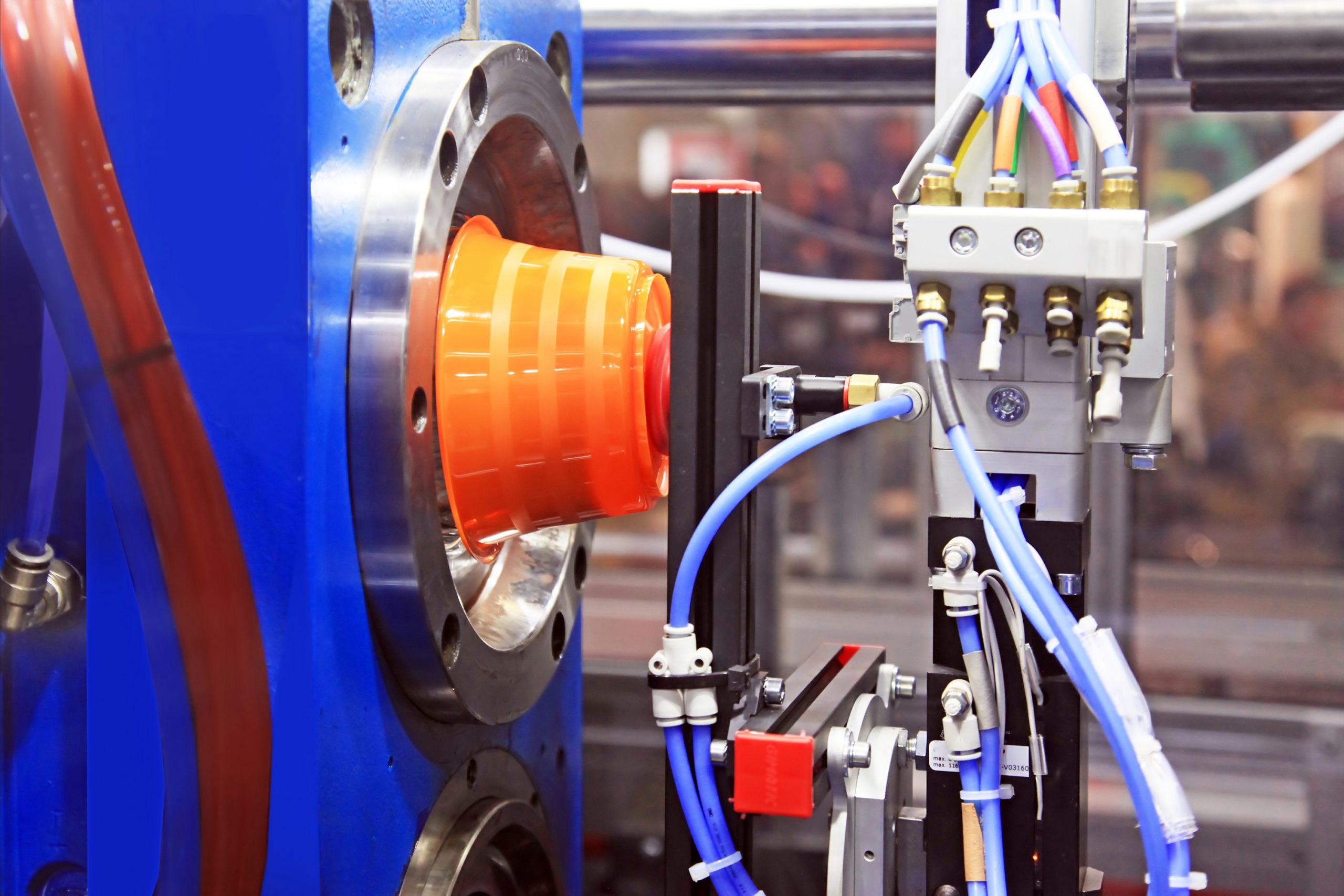

Practical solutions to optimise the workflow of your injection moulding setup

Warped parts

Improper handling

Wasted Material

Slow production runs

Larger profit gains

Increased manufacturing efficiency

Larger scope of work (in-mould labelling)

Higher quality parts

Cutting-edge robotics and automation solutions to optimise your workflow

Reliable and efficient injection moulding machines for a variety of applications

Efficient, accurate and cost effective solutions for in-mould labelling

Eliminating material defects like warping and bubbles with our material drying solutions

Maximise productivity of your operations with our preventative maintenance programs

Just like you, we’ve been frustrated by the inefficiencies of injection moulding.

That's why for the last 16 years we've been helping manufacturing businesses transform themselves into an injection moulding powerhouse.

Need more information about our services or products? Leave a message below and our staff will get in touch with you.